Ceramic Sand

Ceramic Sand is the custom ceramic particles with a spherical shape, high refractoriness and low thermal expansion being made by spraying the melted calcined bauxite. It provides a very simple but efficient way for the foundry-men to improving the quality of the castings, reducing the production cost and avoiding environmental pollution.

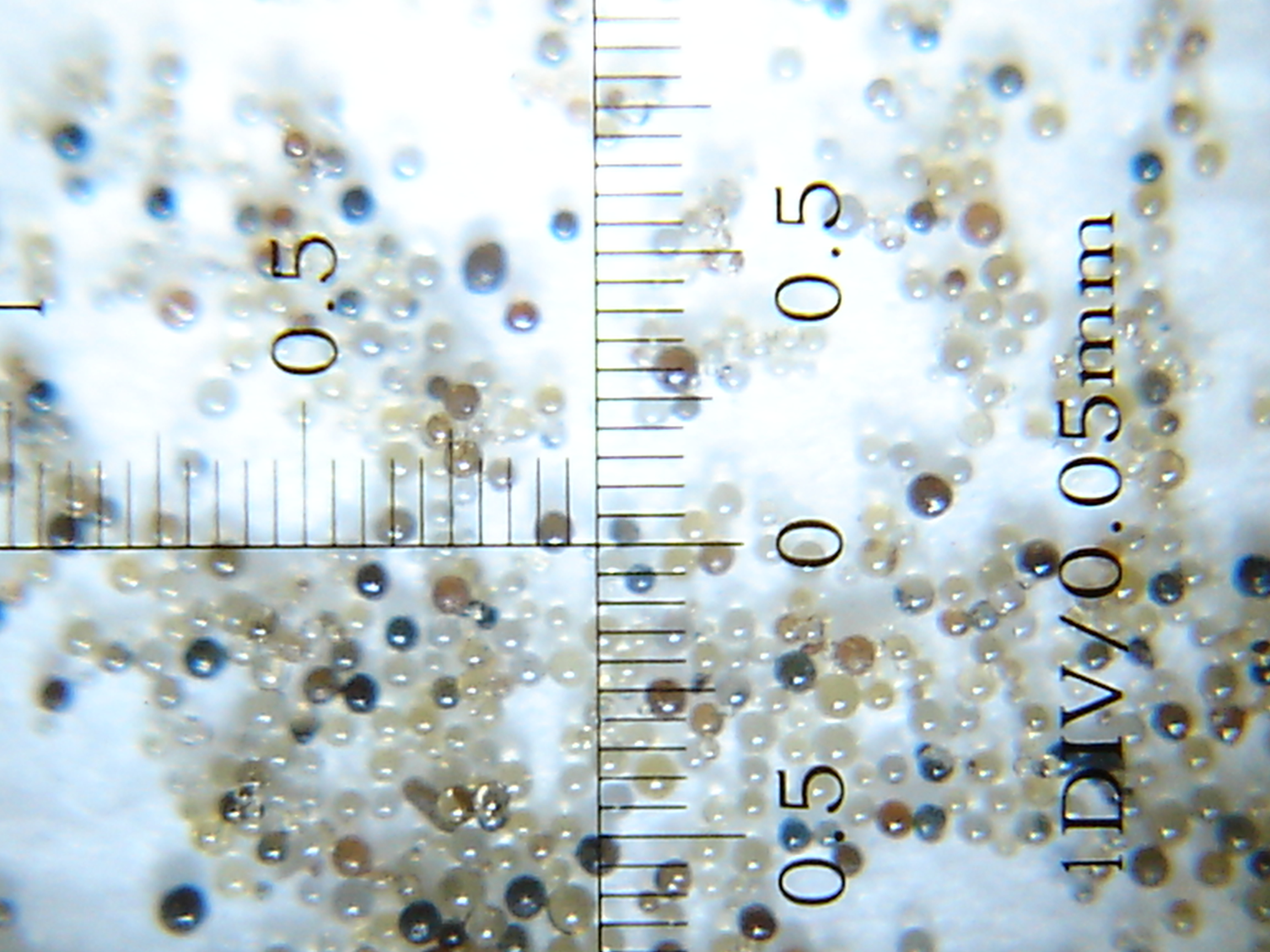

Lost foam casting aims to reduce production costs, improve surface quality, and enhance yield. It uses binder-free dry sand vacuum technology, with common defects like sand inclusion, porosity, slag, and scarring. Choosing the right molding sand is crucial. Traditionally, low-cost silica or magnesium olivine sand is used, but these have issues like low refractoriness, poor fluidity, high dust emission, and low reusability, leading to defects, environmental pollution, and higher overall costs. Application of Fused Ceramic Sand in Lost Foam Casting: Fused ceramic sand, made from high-quality calcined bauxite, is melted and recrystallized in an electric furnace. It offers high refractoriness, excellent fluidity, and superior permeability, effectively reducing casting defects such as inclusions and porosity. Key Properties of Fused Ceramic Sand: • High Refractoriness: Reaches 1800°C, much higher than silica sand, reducing defects and easing cleaning. • Good Liquidity: Spherical particles with excellent fluidity and mold compactness. • Good Air Permeability: Ensures efficient gas evacuation, preventing casting defects. • Low Thermal Expansion: Coefficient of only 0.13%, preventing size deviations. • Environmental Benefits & Recyclability: Produces less dust, less waste, and maintains durability, creating a healthier workspace and reducing energy consumption.

Specifications

Additional Images